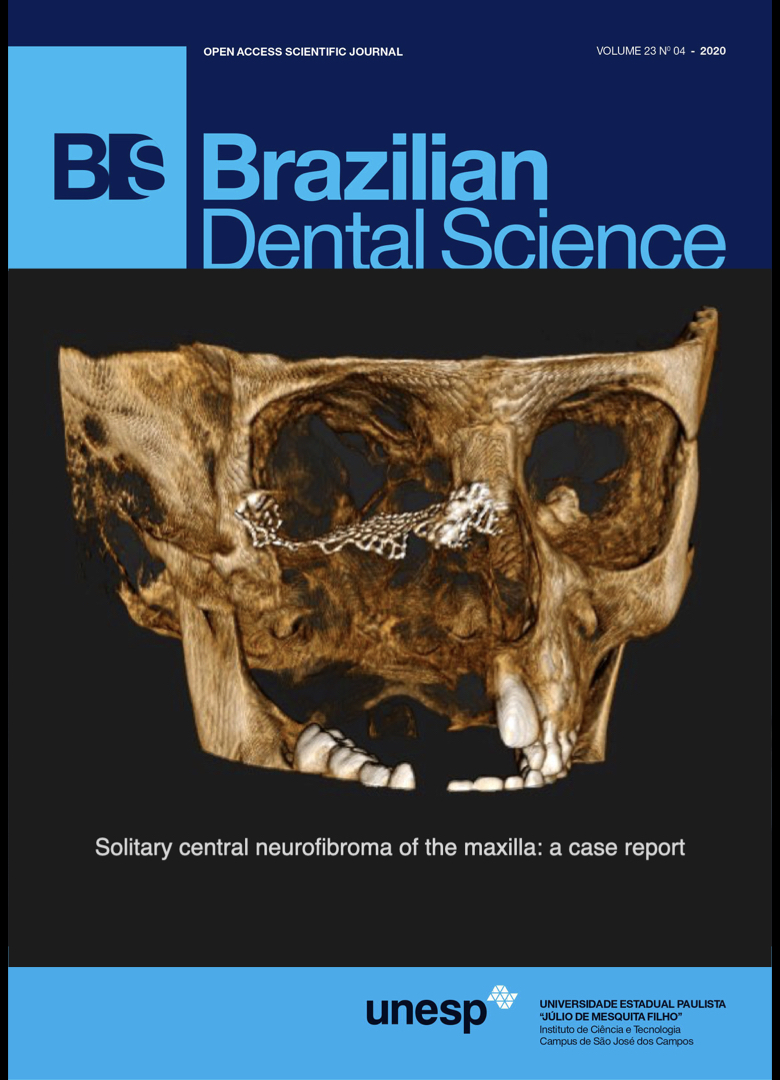

In vitro evaluation of marginal fit of zirconia-reinforced lithium silicate laminate veneers at two thicknesses using different CAD/CAM systems

DOI:

https://doi.org/10.14295/bds.2020.v23i4.2071Abstract

ABSTRACT

Objective: The purpose of this in vitro study was to evaluate the marginal fit of laminate veneers made of zirconia-reinforced lithium silicate with two thicknesses using different CAD/CAM systems. Material and methods: 42 Laminate veneers milled from zirconia-reinforced lithium silicate were divided into three main groups according to milling machine used into: group X5, laminate veneers fabricated by inLab MCX5 milling machine; group CM, laminate veneers fabricated by Ceramill motion 2; and group XL, laminate veneers fabricated by inLab MCXL. Each group was divided into two subgroups according to veneer thickness into: subgroup I, 0.5 mm thickness laminate veneers and subgroup II, 0.3 mm thickness laminate veneers. The marginal fit was measured using stereomicroscope. The results were tabulated and statistically analyzed using two-way ANOVA test followed by Tukey’s post hoc test. Comparisons of main and simple effects were done utilizing Bonferroni correction (P ? 0.05). Results: The mean (±SD) highest marginal discrepancy was recorded in subgroup BII at 85.45±1.82 µm while the least mean marginal discrepancy was recorded in subgroup AI 71.24±2.64 µm. Conclusion: Both thicknesses (0.5 mm thickness and 0.3 mm thickness) and all tested CAD/CAM systems produced zirconia-reinforced lithium silicate laminate veneers with clinically acceptable marginal gaps; however, the closed CAD/CAM systems produced veneers with superior marginal fit than open systems at 0.3 mm thickness. The CAD/CAM system with the 5-axis milling machine produced the best marginal fit with 0.5 mm thickness.

KEYWORDS

Marginal fit; Zirconia-reinforced lithium silicate; Laminate veneers; CAD/CAM; Milling machines.

RESUMO

Objetivo: O objetivo deste estudo in vitro foi avaliar a adaptação marginal de facetas laminadas de silicato de lítio reforçado com zircônia com duas espessuras, utilizando diferentes sistemas CAD / CAM. Material e métodos: 42 facetas laminadas fresadas a partir de silicato de lítio reforçado com zircônia foram divididos em três grupos principais de acordo com a fresadora usada em: grupo X5, facetas laminadas fabricados pela fresadora inLab MCX5; grupo CM, facetas laminadas fabricados por Ceramill motion 2; e grupo XL, facetas laminadas fabricados pelo inLab MCXL. Cada grupo foi dividido em dois subgrupos, de acordo com a espessura do laminado, em: subgrupo I, facetas laminadas com 0,5 mm de espessura e subgrupo II, facetas laminadas com espessura de 0,3 mm. A adaptação marginal foi medida usando estereomicroscópio. Os resultados foram tabulados e analisados estatisticamente usando o teste ANOVA de dois fatores seguido pelo teste post hoc de Tukey. Comparações dos efeitos principais e simples foram realizadas utilizando a correção de Bonferroni (P ?0,05). Resultados: A maior discrepância marginal média (± DP) foi registrada no subgrupo BII em 85,45 ± 1,82 µm, enquanto a menor discrepância marginal média foi registrada no subgrupo AI 71,24 ± 2,64 µm. Conclusão: Ambas as espessuras (0,5 mm e 0,3 mm) e todos os sistemas CAD / CAM testados produziram facetas de laminado de silicato de lítio reforçadas com zircônia com lacunas clinicamente aceitáveis. No entanto, os sistemas CAD / CAM fechados produziam facetas com adaptação marginal superior aos sistemas abertos com 0,3 mm de espessura. O sistema CAD / CAM com a fresadora de 5 eixos produziu a melhor adaptação marginal com 0,5 mm de espessura.

PALAVRAS-CHAVE

Adaptação marginal; Silicato de lítio reforçado com zircônia; Facetas laminados; CAD / CAM; Fresadoras.

Downloads

References

Fons-Font A, Solá-Ruíz MF, Granell-Ruíz M, Labaig-Rueda C, Martínez-González A. Choice of ceramic for use in treatments with porcelain laminate veneers. Med Oral Patol Oral Cir Bucal. 2006;11(3):E297‐E302.

Troedson M, Dérand T. Shear stresses in the adhesive layer under porcelain veneers. A finite element method study. Acta Odontol Scand. 1998;56(5):257‐62. doi:10.1080/000163598428419

Walls AW, Steele JG, Wassell RW. Crowns and other extra-coronal restorations: porcelain laminate veneers. Br Dent J. 2002;193(2):73‐82. doi:10.1038/sj.bdj.4801489

Rosenblum MA, Schulman A. A review of all-ceramic restorations. J Am Dent Assoc. 1997;128(3):297‐307. doi:10.14219/jada.archive.1997.0193

Rizkalla AS, Jones DW. Indentation fracture toughness and dynamic elastic moduli for commercial feldspathic dental porcelain materials. Dent Mater. 2004;20(2):198‐206. doi:10.1016/s0109-5641(03)00092-7

Kelly JR. Dental ceramics: current thinking and trends. Dent Clin North Am. 2004;48(2):viii‐530. doi:10.1016/j.cden.2004.01.003

Sulaiman F, Chai J, Jameson LM, Wozniak WT. A comparison of the marginal fit of In-Ceram, IPS Empress, and Procera crowns. Int J Prosthodont. 1997;10(5):478‐84.

da Costa JB, Pelogia F, Hagedorn B, Ferracane JL. Evaluation of different methods of optical impression making on the marginal gap of onlays created with CEREC 3D. Oper Dent. 2010;35(3):324‐9. doi:10.2341/09-178-L

McLean JW, von Fraunhofer JA. The estimation of cement film thickness by an in vivo technique. Br Dent J. 1971;131(3):107‐11. doi:10.1038/sj.bdj.4802708

Fransson B, Oilo G, Gjeitanger R. The fit of metal-ceramic crowns, a clinical study. Dent Mater. 1985;1(5):197‐9. doi:10.1016/s0109-5641(85)80019-1

Kashani HG, Khera SC, Gulker IA. The effects of bevel angulation on marginal integrity. J Am Dent Assoc. 1981;103(6):882‐5. doi:10.14219/jada.archive.1981.0431

Hamza TA, Sherif RM. In vitro evaluation of marginal discrepancy of monolithic zirconia restorations fabricated with different CAD-CAM systems. J Prosthet Dent. 2017;117(6):762‐6. doi:10.1016/j.prosdent.2016.09.011

Cho HD, Jun YT, Yang MY. Five axis CNC milling for effective milling of sculptured surfaces. Int J Prod Res. 1993;31(11):2559-73. doi: 10.1080/00207549308956883

Martins LM, Lorenzoni FC, Melo AO, Silva LM, Oliveira JL, Oliveira PC, et al. Internal fit of two all-ceramic systems and metal-ceramic crowns. J Appl Oral Sci. 2012;20(2):235-40. doi: 10.1590/s1678-77572012000200019

Murphy E, Ziada HM, Allen PF. Retrospective study on the performance of porcelain laminate veneers delivered by undergraduate dental students. Eur J Prosthodont Restor Dent. 2005;13(1):38-43.

Traini T, Sinjari B, Pascetta R, Serafini N, Perfetti G, Trisi P, et al. The zirconia-reinforced lithium silicate ceramic: lights and shadows of a new material. Dent Mat J. 2016;35(5):748-55. doi: 10.4012/dmj.2016-041

Azarbal A, Azarbal M, Engelmeier RL, Kunkel TC. Marginal fit comparison of CAD/CAM crowns milled from two different materials. J Prosthodont. 2018;27(5):421‐8. doi:10.1111/jopr.12683

Park JM. Comparative analysis on reproducibility among 5 intraoral scanners: sectional analysis according to restoration type and preparation outline form. J Adv Prosthodont. 2016;8(5):354‐62. doi:10.4047/jap.2016.8.5.354

Holden JE, Goldstein GR, Hittelman EL, Clark EA. Comparison of the marginal fit of pressable ceramic to metal ceramic restorations. J Prosthodont. 2009;18(8):645‐8. doi:10.1111/j.1532-849X.2009.00497.x

Piemjai M, Arksornnukit M. Compressive fracture resistance of porcelain laminates bonded to enamel or dentin with four adhesive systems. J Prosthodont. 2007;16(6):457‐64. doi:10.1111/j.1532-849X.2007.00227.x

Pahlevan A, Mirzaee M, Yassine E, Ranjbar Omrany L, Hasani Tabatabaee M, Kermanshah H, et al. Enamel thickness after preparation of tooth for porcelain laminate. J Dent (Tehran). 2014;11(4):428-32.

Yu T, Wang F, Liu Y, Wu T, Deng Z, Chen J. Fracture behaviors of monolithic lithium disilicate ceramic crowns with different thicknesses. RSC Adv 2017;7(41):25542-8. doi: 10.1039/c6ra28847b

Beuer F, Schweiger J, Edelhoff D. Digital dentistry: an overview of recent developments for CAD/CAM generated restorations. Br Dent J. 2008;204(9):505‐11. doi:10.1038/sj.bdj.2008.350

Rinke S, Fornefett D, Gersdorff N, Lange K, Roediger M. Multifactorial analysis of the impact of different manufacturing processes on the marginal fit of zirconia copings. Dent Mater J. 2012;31(4):601-9. doi: 10.4012/dmj.2012-017

Schaefer O, Kuepper H, Thompson GA, Cachovan G, Hefti AF, Guentsch A. Effect of CNC-milling on the marginal and internal fit of dental ceramics: a pilot study. Dent Mater. 2013;29(8):851-8. doi: 10.1016/j.dental.2013.04.018

Kirsch C, Ender A, Attin T, Mehl A. Trueness of four different milling procedures used in dental CAD/CAM systems. Clin Oral Investig. 2017;21(2):551‐8.

Downloads

Published

How to Cite

Issue

Section

License

Brazilian Dental Science uses the Creative Commons (CC-BY 4.0) license, thus preserving the integrity of articles in an open access environment. The journal allows the author to retain publishing rights without restrictions.

=================