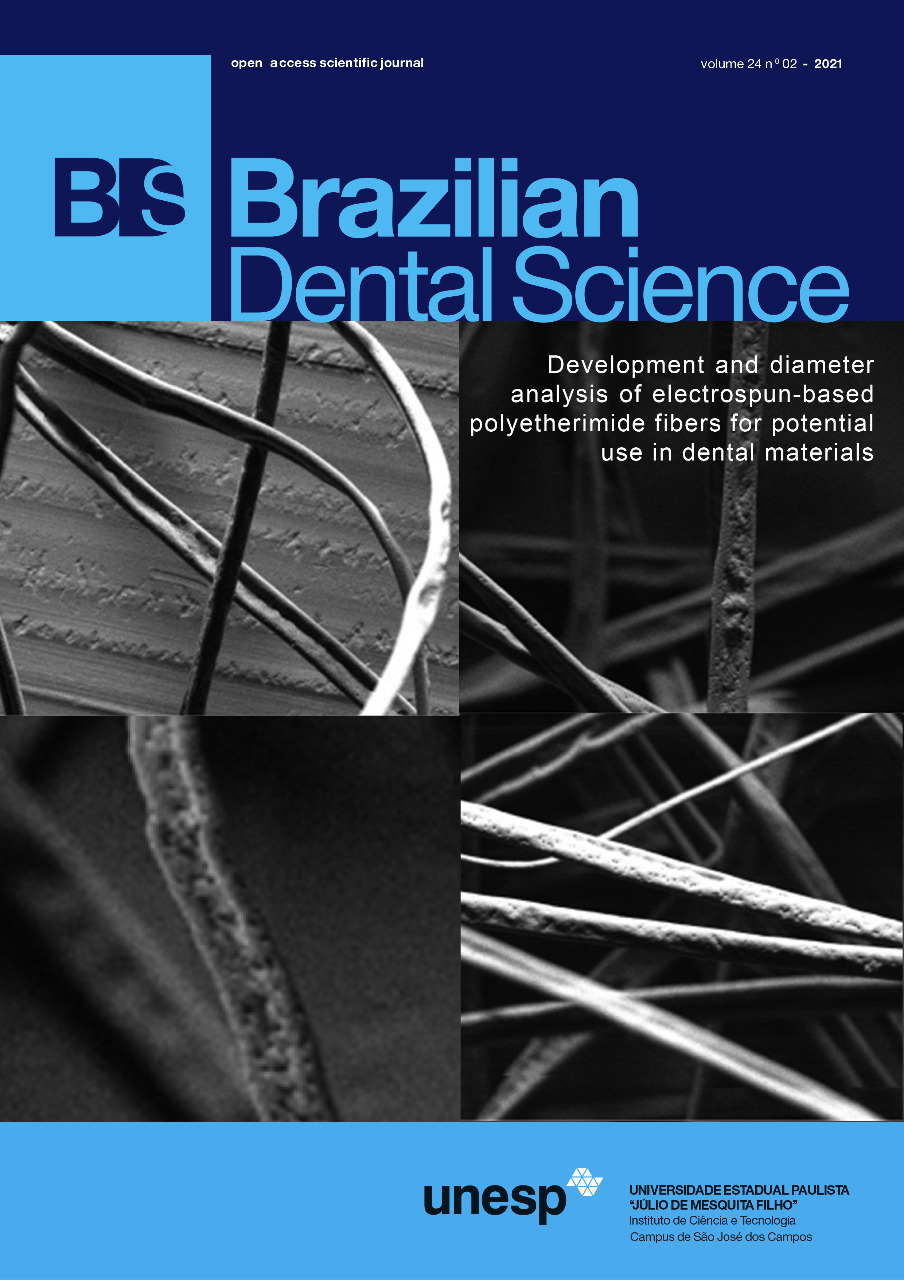

Development of electrospun-based polyetherimide fibers and diameter analysis for potential use in dental materials

DOI:

https://doi.org/10.14295/bds.2021.v24i2.2107Abstract

Objetives: this study aimed to fabricate electrospun-based polyetherimide (PEI) fibers, under controlled parameters, and to perform a diameter analysis for potential mechanical improvement of dental materials. Material and Methods: PEI pallets (0.75 g) were dissolved in 2 mL of chloroform and then processed by electrospinning, under a flow rate of 1mLh1 , three different electrical voltages (10kV, 15kV and 20kV) and three distances (10 cm, 15 cm and 18 cm) between the needle tip and collector. These parameter combinations resulted in nine experimental groups that were analyzed using scanning electron microscopy (SEM) and image processing program for diameter measurement. Statistical analysis was performed using two-way ANOVA with post-hoc Tukey (5% significance). Results: from SEM images it was possible to observe formation of solid, misaligned and flawless defect-free fibers. And from the statistical analysis, distance (p = 0,0026) and the electric tension (p = 0,0012) showed a significant difference, but not for interaction between then (p = 0,4486). Conclusion: thus, it can be concluded that there is a possibility of the morphology control of PEI electrospun fibers, such as diameter, that can be used for a variety of applications such as incorporation in dental materials in order to improve its properties.

Keywords

Electrospinning technique; Fibers; Polyetherimide; Polymer.

Downloads

References

Moraschini V, Fai CK, Alto RM, Dos Santos GO. Amalgam and resin composite longevity of posterior restorations: A systematic review and meta-analysis. Vol. 43, Journal of Dentistry. 2015. p. 1043–50.

Ali Z, Eliyas S, Vere JW illia. Choosing the Right Dental Material and Making Sense of the Options: Evidence and Clinical Recommendations. Eur J Prosthodont Restor Dent. 2015;

Khan AS, Azam MT, Khan M, Mian SA, Rehman IU. An update on glass fiber dental restorative composites: A systematic review. Vol. 47, Materials Science and Engineering C. 2015. p. 26–39.

Santos JD, Sato TP, Lima AL de, Nogueira AS, Quishida CCC, Borges ALS. Titanium Dioxide and Polyethylmethacrylate electrospun nanofibers: assessing the technique parameters and morphological characterization. Brazilian Dent Sci. 2019;

Zhang M, Matinlinna JP. E-Glass Fiber Reinforced Composites in Dental Applications. Silicon. 2012;4(1):73–8.

Sato N, Kurauchi T, Sato S, Kamigaito O. Reinforcing Mechanism by Small Diameter Fiber in Short Fiber Composite. J Compos Mater. 1988;

Thomason JL. The influence of fibre length, diameter and concentration on the impact performance of long glass-fibre reinforced polyamide 6,6. Compos Part A Appl Sci Manuf. 2009;

Uyar T, Çökeliler D, Doʇan M, Koçum IC, Karatay O, Denkbaş EB. Electrospun nanofiber reinforcement of dental composites with electromagnetic alignment approach. Mater Sci Eng C. 2016;62:762–70.

Reneker DH, Yarin AL. Electrospinning jets and polymer nanofibers. Polymer. 2008.

Moon S, Choi J, Farris RJ. Preparation of aligned polyetherimide fiber by electrospinning. J Appl Polym Sci. 2008;109(2):691–4.

Borges ALS, Münchow EA, de Oliveira Souza AC, Yoshida T, Vallittu PK, Bottino MC. Effect of random/aligned nylon-6/MWCNT fibers on dental resin composite reinforcement. J Mech Behav Biomed Mater. 2015;

Johnson RO, Burlhis HS. Polyetherimide: A new high-performance thermoplastic resin. J Polym Sci Polym Symp [Internet]. 2007;70(1):129–43. Available from: http://doi.wiley.com/10.1002/polc.5070700111

De Souza JR, Sato TP, Borges ALS. Scaffold architecture for dental biomaterials: influence of process parameters on the structural morphology of chitosan electrospun fibers. Brazilian Dent Sci. 2017;20(4):100.

Silva JR, Sato TP, Borges ALS. Synthesis and morphological characterization of polycaprolactone (PCL) membranes with tara extract (caesalpinia spinosa). Brazilian Dent Sci. 2019;

Al-Ghafri B, Lau WJ, Al-Abri M, Goh PS, Ismail AF. Titanium dioxide-modified polyetherimide nanofiber membrane for water treatment. J Water Process Eng. 2019;

Kostopoulos V, Kotrotsos A, Fouriki K, Kalarakis A, Portan D. Fabrication and characterization of polyetherimide electrospun scaffolds modified with graphene nano-platelets and hydroxyapatite nano-particles. Int J Mol Sci. 2020;21(2).

Bagheri H, Akbarinejad A, Aghakhani A. A highly thermal-resistant electrospun-based polyetherimide nanofibers coating for solid-phase microextraction Microextraction Techniques. Anal Bioanal Chem. 2014;

Tang X, Qin Y, Xu X, Guo D, Ye W, Wu W, et al. Fabrication and in Vitro Evaluation of 3D Printed Porous Polyetherimide Scaffolds for Bone Tissue Engineering. Biomed Res Int. 2019;2019.

Girotto B. Influência da incorporação de nanofibras de poliamida 6 com e sem nanotubos de carbono como reforço de prótese parcial fixa adesiva. Aleph. 2015;

Li D, Xia Y. Electrospinning of Nanofibers: Reinventing the Wheel? Adv Mater. 2004;16(14):1151–70.

Zhang C, Yuan X, Wu L, Han Y, Sheng J. Study on morphology of electrospun poly(vinyl alcohol) mats. Eur Polym J. 2005;

Reneker DH, Chun I. Nanometre diameter fibres of polymer, produced by electrospinning. Nanotechnology. 1996;

Milleret V, Hefti T, Hall H, Vogel V, Eberli D. Influence of the fiber diameter and surface roughness of electrospun vascular grafts on blood activation. Acta Biomater. 2012;

Wong SC, Baji A, Leng S. Effect of fiber diameter on tensile properties of electrospun poly(ε-caprolactone). Polymer (Guildf). 2008;

WONG, Shing-Chung; BAJI, Avinash; LENG, Siwei. Effect of fiber diameter on tensile properties of electrospun poly (ɛ-caprolactone). Polymer, v. 49, n. 21, p. 4713-4722, 2008.

KIM, Hyung Hwan et al. Effect of fiber diameter on surface morphology, mechanical property, and cell behavior of electrospun poly (ε-caprolactone) mat. Fibers and Polymers, v. 17, n. 7, p. 1033-1042, 2016.

TELES, Maria Carolina Andrade et al. Evaluation of the diameter influence on the tensile strength of pineapple leaf fibers (PALF) by Weibull method. Materials Research, v. 18, p. 185-192, 2015.

Downloads

Published

How to Cite

Issue

Section

License

Brazilian Dental Science uses the Creative Commons (CC-BY 4.0) license, thus preserving the integrity of articles in an open access environment. The journal allows the author to retain publishing rights without restrictions.

=================