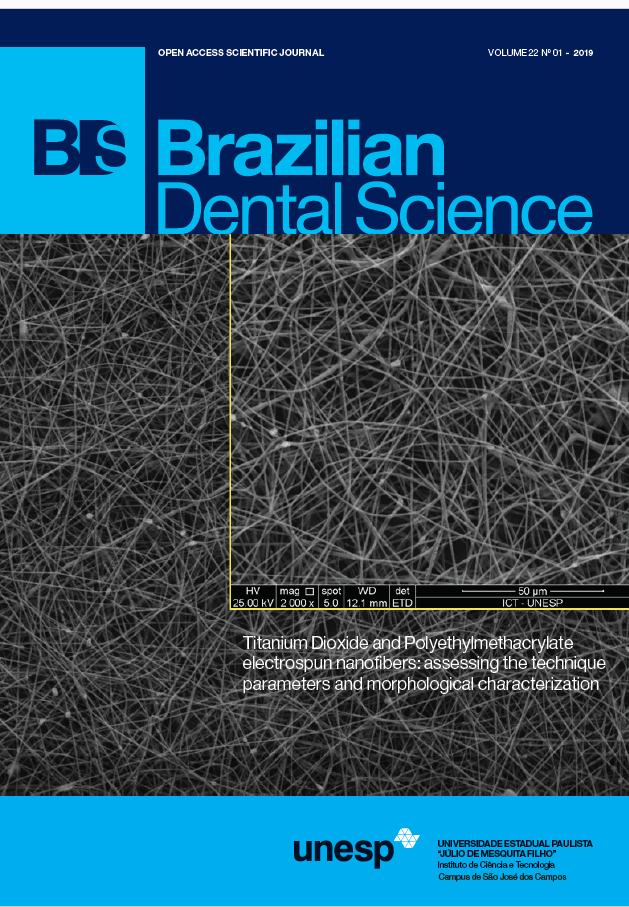

Titanium Dioxide and Polyethylmethacrylate electrospun nanofibers: assessing the technique parameters and morphological characterization

DOI:

https://doi.org/10.14295/bds.2019.v22i1.1630Abstract

This work studied the synthetization and morphological characterization of Polyethylmethacrylate (PEMA) nanofibers (NFs) containing titanium dioxide (TiO2) produced by the electrospinning technique. The solution to produce the nanofibers was prepared by dissolving 2.5g PEMA in 6.75mL of 1.1.2.2- tetrachloroethane and 3.375mL of dimethylformamide (DMF), and 0.405g of TiO2 was added to the solution. The nanofiber production used different distances between the tip of the needle to the collector (10, 12 and 15 cm) and two flow rates (0.05 mLh-1 and 0.08 mLh-1) were employed, while the applied voltage was 17kV. The NF morphology was analyzed by Scanning Electron Microscopy (SEM) and Image J software. We used Fourier Infrared Spectroscopy (FTIR) and Energy Dispersive X-Ray Spectroscopy (EDS) to evaluate the structural properties. All parameters were effective in the NF production, however it was shown that the distance of 12 cm produced the best NFs. The mean diameters showed no statistically significant difference between the samples. The FTIR analysis showed characteristic peaks of PEMA and TiO2. It was concluded that the employed method was efficient for NF production containing PEMA and TiO2,and the morphological characteristics of the NFs were influenced by the voltage and distance.

Keywords

Polymer; Fibers; Electrochemistry.

Downloads

Downloads

Additional Files

Published

How to Cite

Issue

Section

License

Brazilian Dental Science uses the Creative Commons (CC-BY 4.0) license, thus preserving the integrity of articles in an open access environment. The journal allows the author to retain publishing rights without restrictions.

=================